About company

“POLTAVA DIAMOND TOOLS” is a successful company with rich experience, which was founded in 1966.

We specialize in the production of diamond and CBN tools for various industries:

• automotive (production of engines, crankshafts, bearings and other);

• auto components, axial tool;

• aviation (production of turbine blades and various parts);

• energy (production of parts for gas turbine units, cutting of silicon wafers);

• woodworking industry (production and sharpening of wood saws for and cutters);

• glass industry (processing of facade, automotive, design glass, mirrors);

• processing of ceramic tiles, leucosapphire, precious stones;

• oil and gas industry (treatment of drill bits);

• diamond tools for construction and stone processing (diamond wheels for hand tools, professional tools for processing reinforced concrete, granite, marble, asphalt, tiles and other materials.

We produce diamond tools for a wide range of industries, including electronics, medicine, nuclear power and others.

We strive to provide customers with high quality tools by developing innovative solutions and improving production technologies. Our experience and professional skills allow us to meet the needs of the most demanding customers, helping them to improve the efficiency of their production processes and achieve their business goals.

Terms of cooperation

POLTAVA DIAMOND TOOLS – your reliable partner!

We are the leader in the production of diamond tools in Eastern Europe and are ready to offer a wide range of tools for various industrial sectors.

Our main advantages:

• Quality and reliability: All of our products meet the highest quality standards and we guarantee a long service life for our tools. Product Diversity: We offer a wide range of diamond tools suitable for various industries, including mechanical engineering, tool making, woodworking, glassworking, stoneworking, construction, and more.

• Professional approach: Our team consists of experts with many years of experience who are always ready to help you choose the best tool for your needs.

• Client support: We value each client and offer an individual support to each customer. Our customer support team is always ready to answer your questions and help with solving any problems.

• Innovation and Research: We are constantly improving our technology, following the latest industry trends and implementing innovative solutions to provide our customers with the best diamond tools.

If you need a reliable partner for the supply of high quality diamond tools, please contact us by phone +3 487 606 32 11; +1 206 886 08 40 or email sd@pdt.group.

You can find more information on our pdt.tools website.

We are happy to cooperate and ready to help you achieve your production goals!

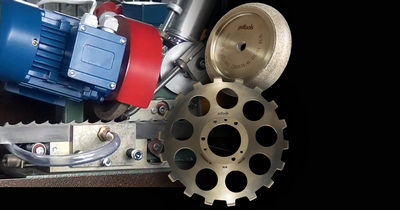

PREMIUM diamond and CBN grinding wheels for the woodworking industry

Diamond and CBN grinding wheels for

high-performance grinding machines of world famous brands

Wheels are used for sharpening:

• circular saws with tungsten carbide tips

• HSS circular saws

• band saw blades with tungsten carbide tips

• for processing of woodcutters, drills and other tools.

The main consumers are:

• specialized service centers for sharpening saws and tools

• saw manufacturers

• chipboard production plants

• furniture companies, etc.

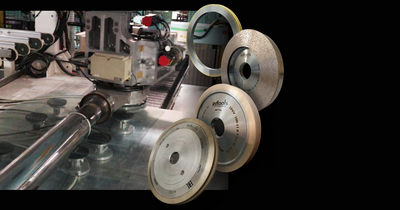

PREMIUM diamond and CBN - grinding wheels for the production of metal cutting tools

Diamond and CBN – grinding wheels for CNC machines.

Wheels are designed for sharpening and production of metal-cutting tools (milling cutters, drills, reamers) made of tungsten carbide and high-speed steel.

The main consumers are:

• companies engaged in the production and sharpening of axial metal-cutting tools

• specialized service centers for sharpening metal-cutting tools

• tool departments of industrial enterprises, etc

Flat grinding with a diamond wheels 1А1

Flat grinding with a diamond wheel is one of the methods for precision grinding of flat surfaces using 1A1 shape diamond wheel. This method is widely used in the industry for processing metals and various materials.

Benefits of grinding with 1A1 diamond wheels from PDTools superabrasives:

• High precision: diamond wheels provide an accurate cutting and minimal deviation in the dimensions of the machined parts

• High productivity: diamond wheels have a high cutting speed and process hard materials effectively

• Durability: diamond wheels have strong wear resistance, which reduces replacement time and improves work efficiency.

Grinding of profiled surfaces with diamond and CBN wheels

Diamond wheels from PDTools superabrasives for grinding shaped hard materials such as steel, cast iron, alloys.

Diamond wheels for profile grinding of metals and alloys are widely used in industry to create complex shapes, profiles or surfaces on various metal products. These wheels have a special design and an abrasive ability that allows precise machining and modeling of metal parts.

When choosing a diamond wheel for profile grinding of metals and alloys, the following factors should be considered:

• type of diamond wheel

• grit size

• bond

• grinding parameters

Diamond dressing rollers

PDTools superabrasives produces a wide range of diamond profiling rollers for such industries as:

Aircraft industry:

• production of turbine blades for aircraft engines

• production of various high-precision parts for the aircraft industry

Automotive and transport engineering:

• production of crankshafts

• production of ball pins

• production of piston rings

• valve manufacturing

• production of gears

• production of bearing parts

Power Engineering

• production of turbine blades for gas pumping stations

Vitrified bonded CBN grinding wheels

Application:

• circular, flat, internal grinding operations

• production of bearing parts

• sharpening of metal-cutting tools

• gear grinding operations

• thread grinding operations

• production of turbine parts, etc.

Main processed materials:

• tool steels

• bearing steels

• titanium alloys

• heat resistant steels

• alloyed steels and other materials

Honing process with diamond hones from PDTools superabrasives

Application of diamond hones:

• Restoration of cylindrical surfaces: diamond honing stones are used for high precision regrind of engine cylinders, hydraulic cylinders and other machine parts.

• Hole honing: diamond stones achieve a smooth finish and precision in internal holes such as bearing seats, sleeves and pipes.

• Flat Surface Finishing: diamond stones are used for honing flat surfaces such as plates, guide rods and tool surfaces.

Benefits of using diamond hones:

• High precision: diamond stones provide high precision machining and the required surface finish.

• Efficiency: fast and efficient honing process using diamond stones, saving time and resources.

• Durability: diamond stones have a long service life and do not require frequent replacement.

Diamond and CBN sharpening stones

PDTools superabrasives has developed and manufactures unique sharpening stones with metal, polyamide bonds with diamond or CBN for sharpening and finishing the cutting edge of kitchen, hunter and other knives, as well as professional hairdressing, manicure and medical tools. In our stones CBN or diamond is fixed in a special unique base, which keeps the grains for a long time and is well enewed. This feature allows the sharpening stone to work long and with high quality.

We can offer two lines of sharpening stones:

• PREMIUM – monolayer stones with a bronze metal bond, diamond or CBN layer of 3 mm thickness.

• EXPERT – monolayer stones with a polyamide (resin) bond with Diamond or CBN of 3mm layer thickness.

Diamond wheels for grinding PCD inserts of drill bits

Restoration of drill bits with PCD (polycrystalline diamond) inserts with diamond wheels is a process of restoring worn or damaged bits using special type 1A1 diamond wheels.

• An innovative solution for restoring of drill bits.

• Maximum productivity: Diamond wheels provide high cutting performance, increasing the efficiency of bit restoration.

• Long service life: Due to the high wear resistance of diamond crystals, the wheels have a long service life, which reduces the cost of tool replacement.

• Accuracy and quality of processing: Diamond wheels provide high precision of processing, allowing high quality restoration of the PCD inserts cutting edges of.

Diamond grinding wheels with elecroplated bond

Electroplated diamond wheels from PDTools superabrasives are special tools used for cutting, grinding and machining various hard materials such as stones, glass, ceramics and various metals.

Electroplated bond means that the diamond grains are attached to the base of the wheel using an electrochemical method, which ensures their reliable fastening and long service life.

Application of diamond wheels with electroplated bond:

• cutting stones and minerals

• cutting glass and ceramics

• metal cutting

• grinding surfaces

• turning and profiling

• surface preparation before coating

Advantages of electroplated diamond wheels: high cutting and grinding accuracy, minimal material destruction, long service life and the ability to process hard-procesing materials.

Diamond wheels with metal bond for glass processing

Diamond wheels are used for glass processing, for example: cutting, grinding, turning, drilling, engraving, creating edges and grinding glass products.

Application:

• automotive glass processing

• processing of architectural sheet glass

• processing of designer glass in the production of furniture

• mirror processing

• processing of optical lenses

• crystal processing

• processing of glassware, etc.

The main consumers are:

• sheet glass manufacturers

• furniture manufacturers

• factories for the production of optical instruments

• crystal processing plants, etc.

Diamond wheels for grinding precious and semi-precious stones

PDTools superabrasives manufactures diamond wheels in various shapes for cutting, grinding and polishing gem stones.

Application:

• processing of flat and shaped surfaces

• glass products

• ceramics

• quartz

• precious and ornamental stones

The diamond layer is made of diamond grinding powders and micropowders with metal bonds.

Processing of concrete with a diamond tool

The main advantage of diamond tools is their ability to process concrete at high speed and productivity, while providing a quality result.

Application of diamond tools:

• concrete cutting diamond wheels which are used to cut concrete slabs, walls, curbs and other building constructions. Diamond wheels can be mounted on petrol cutters, electric saws or angle grinders.

• diamond wheels are used to remove roughness and grind concrete to achieve a smooth surface.

• diamond core drill bits are used to drill holes in concrete for laying pipes or installing anchors. Diamond core drill bits allow you to drill concrete surfaces more efficiently and accurately.

Processing of stone and natural materials with diamond tools

Diamond tools are widely used for processing natural stones such as granite, marble, slate and other natural materials.

Processing of natural stone materials using diamond tools provides a high-quality and fast cutting.

Advantages of diamond tools from PDTools superabrasives:

• High hardness: diamonds are one of the hardest materials on the Earth, they make tools durable and wear resistant

• High Precision: diamond tools enable precise machining operations to achieve a high quality finish.

• Wide range of applications: diamond tools can be used on a variety of materials, including granite, marble, slate and other natural stones.

Processing of natural stone materials:

• discs are used for cutting various natural stone materials such as granite, marble, slate, limestone and others. Cutting can be done by hand using angle grinders or special cutting machines.

• there are diamond segments for circular saws of large diameters 1000-3000 mm.

Processing of ceramic tiles with diamond tools

Processing of ceramic tiles with diamond wheels from PDTools superabrasives provides good result.

The range includes wheels for grinding machines, as well as for stationary and industrial equipment.

The company manufactures tools for different application tasks.

There are several diamond product lines:

• Slim, Relief, Elite as well as product line for stationary equipment

• Ceramic Hard PRO – the ideal solution for cutting of porcelain tile

• Ceramic Max PRO – high-speed cutting of porcelain tile with a thickness of 20mm and above

• Ceramic Clean PRO – perfectly clean edge of glossy tile and porcelain tile

About company

“POLTAVA DIAMOND TOOLS” is a successful company with rich experience, which was founded in 1966.

We specialize in the production of diamond and CBN tools for various industries:

• automotive (production of engines, crankshafts, bearings and other);

• auto components, axial tool;

• aviation (production of turbine blades and various parts);

• energy (production of parts for gas turbine units, cutting of silicon wafers);

• woodworking industry (production and sharpening of wood saws for and cutters);

• glass industry (processing of facade, automotive, design glass, mirrors);

• processing of ceramic tiles, leucosapphire, precious stones;

• oil and gas industry (treatment of drill bits);

• diamond tools for construction and stone processing (diamond wheels for hand tools, professional tools for processing reinforced concrete, granite, marble, asphalt, tiles and other materials.

We produce diamond tools for a wide range of industries, including electronics, medicine, nuclear power and others.

We strive to provide customers with high quality tools by developing innovative solutions and improving production technologies. Our experience and professional skills allow us to meet the needs of the most demanding customers, helping them to improve the efficiency of their production processes and achieve their business goals.

Terms of cooperation

POLTAVA DIAMOND TOOLS – your reliable partner!

We are the leader in the production of diamond tools in Eastern Europe and are ready to offer a wide range of tools for various industrial sectors.

Our main advantages:

• Quality and reliability: All of our products meet the highest quality standards and we guarantee a long service life for our tools. Product Diversity: We offer a wide range of diamond tools suitable for various industries, including mechanical engineering, tool making, woodworking, glassworking, stoneworking, construction, and more.

• Professional approach: Our team consists of experts with many years of experience who are always ready to help you choose the best tool for your needs.

• Client support: We value each client and offer an individual support to each customer. Our customer support team is always ready to answer your questions and help with solving any problems.

• Innovation and Research: We are constantly improving our technology, following the latest industry trends and implementing innovative solutions to provide our customers with the best diamond tools.

If you need a reliable partner for the supply of high quality diamond tools, please contact us by phone +3 487 606 32 11; +1 206 886 08 40 or email sd@pdt.group.

You can find more information on our pdt.tools website.

We are happy to cooperate and ready to help you achieve your production goals!

PREMIUM diamond and CBN grinding wheels for the woodworking industry

Diamond and CBN grinding wheels for

high-performance grinding machines of world famous brands

Wheels are used for sharpening:

• circular saws with tungsten carbide tips

• HSS circular saws

• band saw blades with tungsten carbide tips

• for processing of woodcutters, drills and other tools.

The main consumers are:

• specialized service centers for sharpening saws and tools

• saw manufacturers

• chipboard production plants

• furniture companies, etc.

PREMIUM diamond and CBN - grinding wheels for the production of metal cutting tools

Diamond and CBN – grinding wheels for CNC machines.

Wheels are designed for sharpening and production of metal-cutting tools (milling cutters, drills, reamers) made of tungsten carbide and high-speed steel.

The main consumers are:

• companies engaged in the production and sharpening of axial metal-cutting tools

• specialized service centers for sharpening metal-cutting tools

• tool departments of industrial enterprises, etc

Flat grinding with a diamond wheels 1А1

Flat grinding with a diamond wheel is one of the methods for precision grinding of flat surfaces using 1A1 shape diamond wheel. This method is widely used in the industry for processing metals and various materials.

Benefits of grinding with 1A1 diamond wheels from PDTools superabrasives:

• High precision: diamond wheels provide an accurate cutting and minimal deviation in the dimensions of the machined parts

• High productivity: diamond wheels have a high cutting speed and process hard materials effectively

• Durability: diamond wheels have strong wear resistance, which reduces replacement time and improves work efficiency.

Grinding of profiled surfaces with diamond and CBN wheels

Diamond wheels from PDTools superabrasives for grinding shaped hard materials such as steel, cast iron, alloys.

Diamond wheels for profile grinding of metals and alloys are widely used in industry to create complex shapes, profiles or surfaces on various metal products. These wheels have a special design and an abrasive ability that allows precise machining and modeling of metal parts.

When choosing a diamond wheel for profile grinding of metals and alloys, the following factors should be considered:

• type of diamond wheel

• grit size

• bond

• grinding parameters

Diamond dressing rollers

PDTools superabrasives produces a wide range of diamond profiling rollers for such industries as:

Aircraft industry:

• production of turbine blades for aircraft engines

• production of various high-precision parts for the aircraft industry

Automotive and transport engineering:

• production of crankshafts

• production of ball pins

• production of piston rings

• valve manufacturing

• production of gears

• production of bearing parts

Power Engineering

• production of turbine blades for gas pumping stations

Vitrified bonded CBN grinding wheels

Application:

• circular, flat, internal grinding operations

• production of bearing parts

• sharpening of metal-cutting tools

• gear grinding operations

• thread grinding operations

• production of turbine parts, etc.

Main processed materials:

• tool steels

• bearing steels

• titanium alloys

• heat resistant steels

• alloyed steels and other materials

Honing process with diamond hones from PDTools superabrasives

Application of diamoned hones:

• Restoration of cylindrical surfaces: diamond honing stones are used for high precision regrind of engine cylinders, hydraulic cylinders and other machine parts.

• Hole honing: diamond stones achieve a smooth finish and precision in internal holes such as bearing seats, sleeves and pipes.

• Flat Surface Finishing: diamond stones are used for honing flat surfaces such as plates, guide rods and tool surfaces.

Benefits of using diamond hones:

• High precision: diamond stones provide high precision machining and the required surface finish.

• Efficiency: fast and efficient honing process using diamond stones, saving time and resources.

• Durability: diamond stones have a long service life and do not require frequent replacement.

Diamond and CBN sharpening stones

PDTools superabrasives has developed and manufactures unique sharpening stones with metal, polyamide bonds with diamond or CBN for sharpening and finishing the cutting edge of kitchen, hunter and other knives, as well as professional hairdressing, manicure and medical tools. In our stones CBN or diamond is fixed in a special unique base, which keeps the grains for a long time and is well enewed. This feature allows the sharpening stone to work long and with high quality.

We can offer two lines of sharpening stones:

• PREMIUM – monolayer stones with a bronze metal bond, diamond or CBN layer of 3 mm thickness.

• EXPERT – monolayer stones with a polyamide (resin) bond with Diamond or CBN of 3mm layer thickness.

Diamond wheels for grinding PCD inserts of drill bits

Restoration of drill bits with PCD (polycrystalline diamond) inserts with diamond wheels is a process of restoring worn or damaged bits using special type 1A1 diamond wheels.

• An innovative solution for restoring of drill bits.

• Maximum productivity: Diamond wheels provide high cutting performance, increasing the efficiency of bit restoration.

• Long service life: Due to the high wear resistance of diamond crystals, the wheels have a long service life, which reduces the cost of tool replacement.

• Accuracy and quality of processing: Diamond wheels provide high precision of processing, allowing high quality restoration of the PCD inserts cutting edges of.

Diamond grinding wheels with elecroplated bond

Electroplated diamond wheels from PDTools superabrasives are special tools used for cutting, grinding and machining various hard materials such as stones, glass, ceramics and various metals.

Electroplated bond means that the diamond grains are attached to the base of the wheel using an electrochemical method, which ensures their reliable fastening and long service life.

Application of diamond wheels with electroplated bond:

• cutting stones and minerals

• cutting glass and ceramics

• metal cutting

• grinding surfaces

• turning and profiling

• surface preparation before coating

Advantages of electroplated diamond wheels: high cutting and grinding accuracy, minimal material destruction, long service life and the ability to process hard-procesing materials.

Diamond wheels with metal bond for glass processing

Diamond wheels are used for glass processing, for example: cutting, grinding, turning, drilling, engraving, creating edges and grinding glass products.

Application:

• automotive glass processing

• processing of architectural sheet glass

• processing of designer glass in the production of furniture

• mirror processing

• processing of optical lenses

• crystal processing

• processing of glassware, etc.

The main consumers are:

• sheet glass manufacturers

• furniture manufacturers

• factories for the production of optical instruments

• crystal processing plants, etc.

Diamond wheels for grinding precious and semi-precious stones

PDTools superabrasives manufactures diamond wheels in various shapes for cutting, grinding and polishing gem stones.

Application:

• processing of flat and shaped surfaces

• glass products

• ceramics

• quartz

• precious and ornamental stones

The diamond layer is made of diamond grinding powders and micropowders with metal bonds.

Processing of concrete with a diamond tool

The main advantage of diamond tools is their ability to process concrete at high speed and productivity, while providing a quality result.

Application of diamond tools:

• concrete cutting diamond wheels which are used to cut concrete slabs, walls, curbs and other building constructions. Diamond wheels can be mounted on petrol cutters, electric saws or angle grinders.

• diamond wheels are used to remove roughness and grind concrete to achieve a smooth surface.

• diamond core drill bits are used to drill holes in concrete for laying pipes or installing anchors. Diamond core drill bits allow you to drill concrete surfaces more efficiently and accurately.

Processing of stone and natural materials with diamond tools

Diamond tools are widely used for processing natural stones such as granite, marble, slate and other natural materials.

Processing of natural stone materials using diamond tools provides a high-quality and fast cutting.

Advantages of diamond tools from PDTools superabrasives:

• High hardness: diamonds are one of the hardest materials on the Earth, they make tools durable and wear resistant

• High Precision: diamond tools enable precise machining operations to achieve a high quality finish.

• Wide range of applications: diamond tools can be used on a variety of materials, including granite, marble, slate and other natural stones.

Processing of natural stone materials:

• discs are used for cutting various natural stone materials such as granite, marble, slate, limestone and others. Cutting can be done by hand using angle grinders or special cutting machines.

• there are diamond segments for circular saws of large diameters 1000-3000 mm.

Processing of ceramic tiles with diamond tools

Processing of ceramic tiles with diamond wheels from PDTools superabrasives provides good result.

The range includes wheels for grinding machines, as well as for stationary and industrial equipment.

The company manufactures tools for different application tasks.

There are several diamond product lines:

• Slim, Relief, Elite as well as product line for stationary equipment

• Ceramic Hard PRO – the ideal solution for cutting of porcelain tile

• Ceramic Max PRO – high-speed cutting of porcelain tile with a thickness of 20mm and above

• Ceramic Clean PRO – perfectly clean edge of glossy tile and porcelain tile