Application of diamond and CBN tools and their advantages over abrasive tools

APPLICATION OF DIAMOND TOOLS AND THEIR ADVANTAGES OVER ABRASIVE TOOLS

- Processing, sharpening and finishing of tools made of all alloy types.

- Sharpening and finishing of carbide tools.

- Processing and cutting of silicon, germanium and other semiconducting

- Processing, cutting and finishing of tools made of ferrite, ceramic and glass materials.

- Processing of graphite and carbon reinforced plastics.

- Processing and cutting of reinforced fiber glass plastics, fiberplastics.

- Finishing and polishing of precious stones.

- Cutting, finishing and polishing of artificial and natural stones.

- Processing of all types of decorative and technical glasses and porcelain.

- Cutting and processing of all types of refractory materials.

ADVANTAGES OF DIAMOND GRINDING TOOLS OVER ABRASIVE TOOLS

- High wear resistance.

- Workpiece life longer after diamond tool profiling.

- Less thermal workpiece damage due to lower temperature in grinding zone.

- Longer lasting, hence reduced changeover times.

- Higher volumes at the same level of quality.

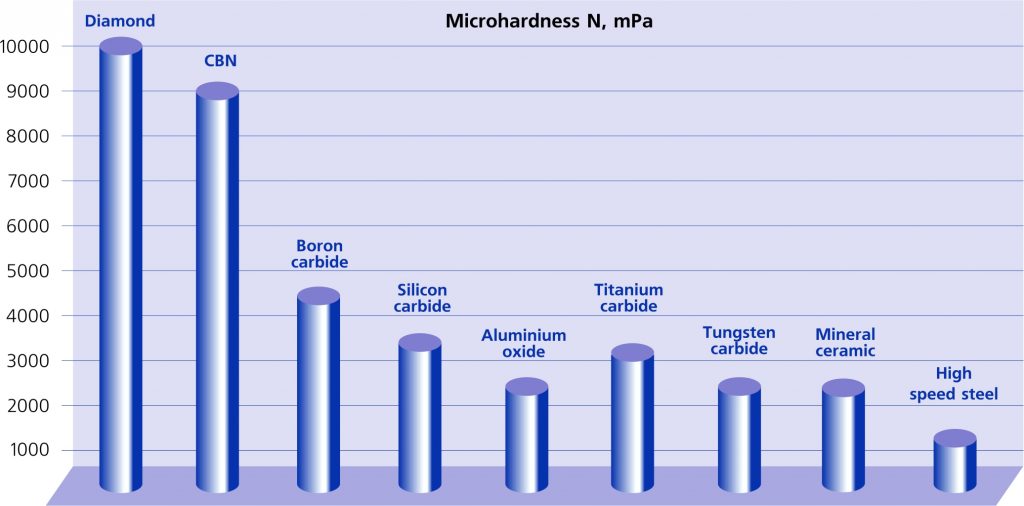

PHYSICOMECHANICAL CHARACTERISTICS OF ABRASIVE TOOL MATERIALS